-

Elevator Stainless Steel Sheet

-

Water Ripple Stainless Steel Sheet

-

Etched Stainless Steel Sheet

-

Cold Rolled Stainless Steel Plate

-

Stainless Steel Tile Trim

-

Embossed Stainless Steel Sheet

-

Hairline Stainless Steel Sheet

-

Stainless Steel Metal Fabrication

-

Decorative Stainless Steel Sheet

-

Coloured Stainless Steel Sheet

-

Stainless Steel Room Divider

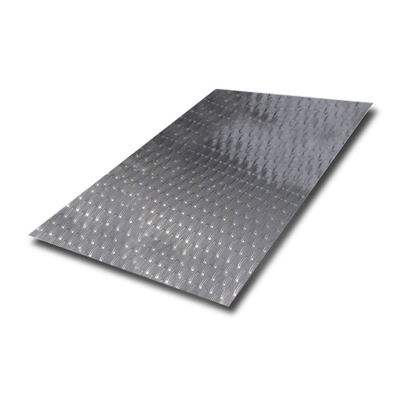

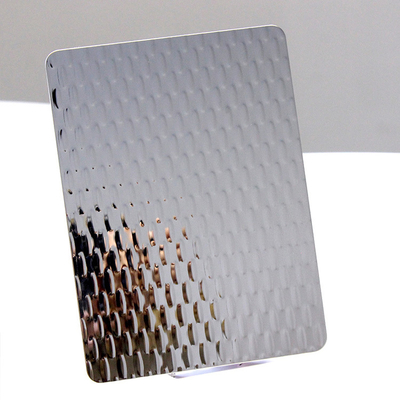

Silver Mirror 5WL Stamped Decorative Stainless Steel Plate Sustainable

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Type | Decorative Stainless Steel Sheet | Standard | ASTM, AISI, GB, JIS, DIN, EN |

|---|---|---|---|

| Grade | 304 Stainless Steel | Shape | Plate |

| Technique | Mirror/Stamped/PVD Color Coated | Surface Treatment | Mirror/Stamped/PVD Color Coated |

| Color Coating | Silver/Gold | PVC Film | Double 70 Micron Black And White PVC |

| Thickness | 0.65mm | Size | 1000x2000mm/1219x2438mm |

| Highlight | Sustainable Decorative Stainless Steel Plate,5WL Stamped Decorative Stainless Steel Plate,Silver Mirror Decorative Stainless Steel Plate |

||

Silver Mirror 5WL Stamped Decorative Stainless Steel Plate Sustainable

- Type: Decorative Stainless Steel Sheet

- Feature: Sustainable

- Size:1219x2438mm

- Packing:Wooden Case

- Technique: Cold Rolled/PVD Color Coating/Stamped/Polish

- Grade:304 Stainless Steel

- Packing:According to customers' needs, use wrapping paper. If the transportation period exceeds 10 days or encounters special climate, we will use waterproof packaging and add plastic film to prevent moisture, water and rust.

PVD coated color stainless steel is used in the creation of sculpture, architecture, jewelry, phones and is used for interiors and exteriors.

| Type | Decorative Stainless Steel Sheet | Standard | ASTM, AISI, GB, JIS, DIN, EN |

| Grade | 304 Stainless Steel | Texture | Customized |

| Technique | Cold Rolled/PVD Color Coating/Stamped/Polish | Color Coating | Silver/Gold/Rose/Champagne Gold/Black |

| Surface Treatment | Mirror | Regular Size | 1219x2438mm/1500x3000mm |

| Usage | Ceiling/Wall | Packing | Wooden Case |

| Original Material |

POSCO/JISCO/TISCO/LISCO/BAOSTEEL etc |

PVC Film |

Laser PVC/POLI-FILM/NOVANCEL/PVC thickness 70-100 Micron Laser PVC/Double 70 Micron Black And White PVC |

| Chemical composition and mechanical properties of stainless steel coils | |||||||||

| Grade | Chemical Composition (%) | Mechanical Performance | |||||||

| C | Si | Mn | P | S | Ni | Cr | Mo | Hardness | |

| 201 | ≤0.15 | ≤1.00 | 5.5/7.5 | ≤0.060 | ≤0.030 | 3.5/5.5 | 16.0/18.0 | - | HB≤241,HRB≤100, HV≤240 |

| 304 | ≤0.08 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.03 | 8.0/11.0 | 18.00/20.00 | - | HB≤187,HRB≤90,HV≤200 |

| 316 | ≤0.08 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.03 | 10.00/14.00 | 16.0/18.0 | 2.00/3.00 | HB≤187, HRB≤90 HV≤200 |

| 316L | ≤0.03 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.03 | 10.00/14.00 | 16.0/18.0 | 2.00/3.00 | HB≤187, HRB≤90 HV≤200 |

| 410 | ≤0.15 | ≤1.00 | ≤1.25 | ≤0.060 | ≤0.030 | ≤0.060 | 11.5/13.5 | - | HB≤183, HRB≤88 HV≤200 |

| 430 | ≤0.12 | ≤1.00 | ≤1.25 | ≤0.040 | ≤0.03 | - | 16.00/18.00 | - | HB≤183, HRB≤88 HV≤200 |

|

Surface |

Definition |

Application |

| 2B |

Finished by heat treatment , picking or equivalent cold rolling , followed by skin pass to obtain adequate luster surface.

|

With bright and smooth surface ,easy for further grinding to obtain brighter surface ,suitable for medical instruments ,milk containers ,tableware and so on.

|

| BA |

Bright heat treatment after cold rolling.

|

Structural members .etc.kitchen utensil ,cutlery ,electric appliances ,medical instruments ,building decorations ,etc.

|

| NO.3/NO.4 |

Polished with No.150-240 abrasives.

|

Milky food processing equipment , medical instruments ,building decorations.

|

| HL |

Finished by polishing with abrasives of suitable grain size to obtain continuous streaks.

|

Building decorations ,such as elevators ,escalators ,door etc.

|

| 6K/8K |

A mirror-like reflective surface ,which is obtained by polishing with successively finer abrasives and buffing extensively with all grit lines are removed.

|

Building entrances,bulking column casting ,elevator's wall doors ,counters,sculptures etc. |

![]()

![]()

![]()

![]()

![]()

FAQ

Q1: WHO IS MEIBAOTAI ?

A1: Meibaotai Stainless Steel Products Co., Ltd.,which is the largest stainless steel products manufacturing and storing base for South China.

Q2: COULD WE GET A SAMPLE BEFORE A FORMAL ORDER?

A2: Yes, we can provide a sample before order. Checking a sample is a best way to understand the detail quality.

Q3:WHAT TYPES OF PAYMENT DO YOU ACCEPT?

A3:The types of payment we usually use L/C and T/T.

Q4:WHAT IS YOUR TERMS OF DELIVERY?

A4:EXW, FOB, CFR, CIF.

Q5:WHERE ARE YOUR PRODUCTS MAINLY EXPORTED TO?

A5:We have exported to over 30 countries, mainly in, Middle East, Asia, Europe.

Q6:WHAT IS THE MOQ?

A6:If you are scheduling to place a small quantity order or trial order, feel free to contact us, we can meet your requirements.

Q7:HOW CAN YOU ENSURE THE QUALITY OF YOUR PRODUCT?

A7:We'll keep tracing feedback of our products from clients and that's what make us different from other suppliers.We're customer care enterprise.

Q8:WHERE IS MEIBAOTAI LOCATED?

A8:Our company located in FOSHAN GUANGDONG CHINA.

Factory Address: A2-3 Factory Building, Sanshan Huadao North Road, Nanhai Distrct, Foshan City, Guangdong Provenice, China

Export Office Address: Room 1919, Floor 19, Veinna building, Chencun, Shunde, Foshan, Guangdong, China.

Q9. HOW CAN YOU CONTRAL COLOR?

A9.We control by technical, the color combined by LAB(color data), we make sure LAB within tolerance and then color will be look the same.

Q10.HOW CAN YOU ENSURE THE QUALITY OF YOUR PRODUCT?

A10.All products have to go through three checks in the whole manufacturing process,it includes production,cutting sheets and the packing.

Description Of Stamped Stainless Steel Sheet

Stamped is a stainless steel forming process for producing raised or sunken designs in stainless steel sheet material by passing through stamped machine. Stamped stainless steel sheet is a type of decorative stainless steel sheet that has been mechanically embossed or indented with patterns, textures, or designs. The stamping process involves pressing a pattern into the stainless steel using a die, resulting in a raised or recessed design. This technique is widely used for both functional and decorative purposes, providing a combination of aesthetic appeal and enhanced physical properties.

Advantage Of Stamped Stainless Steel Sheet

Stamped can be proceed on 2B, mirror or NO.4 stainless steel sheet surfaces, and do PVD coating after stamped.

MEIBAOTAI also supplies stamped stainless steel fabrication such as laser cutting, bending, welding and other CNC machinery service.

Application Of Stamped Stainless Steel Sheet

Stamped stainless steel sheet is widely used in academic residential buildings, airport, train, lobby, sculpture, tube , internal structures and fittings, luxury interior and bars decoration, shop counter, machinery, catering vehicles.

Stamped, a process whereby a pattern is pressed into the surface of stainless steel by rolling or stamping.

Stainless steel sheet packaging and loading

1 Stainless steel sheets covered with wooden plate for protection in transportation.

2. All stainless steel sheets will be loaded in strong wooden packages.

3. Every cartons loaded with good shoring and strengthening.

4. Take container loading pictures and seal the container.

5. Transportation speed is quick. And keep customer each step informed.